Navigating FSMA Compliance with Wireless Power Networks

The Food Safety Modernization Act (FSMA) is one of the most significant reforms in food safety, shifting the focus from reaction to prevention. According to the FDA, each year, 48 million Americans (1 in 6) suffer from foodborne illnesses, leading to 128,000 hospitalizations and 3,000 deaths—many of which are preventable.

With compliance deadlines already in effect and stricter enforcement looming, businesses must act now. Meeting FSMA’s rigorous requirements—spanning traceability, transportation, and environmental monitoring—is essential to prevent costly recalls, legal penalties, and reputational damage. Delaying compliance not only increases financial risk but also endangers public health.

Understanding FSMA Compliance

FSMA is a comprehensive reform designed to modernize food safety systems, emphasizing prevention at every stage of the supply chain. The act introduces several critical rules, including:

• Traceability requirements: Businesses must maintain detailed records of food origins and movements to enable rapid recalls in the event of contamination.

• Sanitary Transportation Rule: FSMA mandates strict environmental conditions, such as temperature and humidity controls, during transportation to prevent spoilage.

• Record keeping and reporting: Accurate data collection is essential to demonstrate compliance, and failure to meet FDA record inquiries within 24 hours is considered a “prohibited act” with serious legal consequences.

Non-compliance can lead to severe penalties, including FDA facility suspension, preventing businesses from distributing food and causing significant financial losses. Many companies relying on manual tracking or outdated compliance systems may struggle to meet FSMA’s rapid response requirements, putting them at heightened risk.

The only way to ensure compliance and avoid penalties is through real-time, automated data collection—a capability that Wireless Power Networks (WPNs) uniquely enable. By continuously powering IoT sensors that monitor food safety metrics 24/7, WPNs help businesses meet FSMA mandates, reduce compliance risks, and protect public health.

Challenges Businesses Face in FSMA Compliance

Implementing FSMA requirements can be particularly challenging for businesses across the supply chain due to:

- Complexity of traceability: Maintaining detailed records of food movements is labor-intensive and prone to errors, especially when done manually. A recent study found that 48% of food and beverage suppliers still rely on manual spreadsheets, with over 65% of companies citing regulatory changes such as IoT-level traceability as a reason they’re looking for modern solutions. (SupplyChain247)

- Environmental monitoring during transportation: Ensuring optimal conditions for food storage and transport requires constant oversight and reliable equipment. Globally, an estimated 30% of food produced for human consumption is lost or wasted along the supply chain, leading to significant financial losses. (CMTC.com)

- Maintenance of monitoring devices: Many conventional devices depend on wired power or batteries, leading to frequent replacements, downtime, and high maintenance costs.

Currently, many food industry businesses rely on manual recordkeeping, standalone sensors, and battery-powered monitoring devices to track compliance with FSMA regulations. However, manual processes increase the risk of human error, leading to gaps in traceability and inaccurate reporting. Standalone sensors, while useful, require frequent manual checks and maintenance, making real-time monitoring difficult. Battery-powered devices introduce additional challenges, as power failures or depleted batteries can lead to undetected compliance violations.

Given these limitations, businesses need a more reliable and continuous solution to ensure compliance, reduce operational burdens, and protect food safety throughout the supply chain.

The Role of Wireless Power Netowrks and IoT in Food Safety

WPNs are simplifying FSMA compliance by eliminating the limitations of wired and battery-powered asset and inventory tracking and management systems. WPNs provide a reliable, always-on power source for IoT applications, providing businesses with real-time data analytics and automated monitoring for critical sensors, tags, and other connected devices. This enables reliable tracking of environmental conditions, product movement, and regulatory reporting—helping businesses overcome key food safety challenges with greater efficiency and accuracy.

WPNs use forms of over-the-air power such as Infrared (IR) charging or radio frequency (RF) waves to deliver energy to devices without the need for physical connections. They power IoT-enabled devices and communicate with gateways that collect and transmit critical data to the cloud in real-time. Key components of a WPN include:

Benefits of Wireless Power and IoT for FSMA Compliance

Wireless power and IoT offer key advantages that not only deliver seamless FSMA compliance but also improve overall operational efficiency:

- Enhanced traceability: IoT tags and sensors can automatically track the location and movement of food products, providing accurate, real-time data that reduces the need for manual recordkeeping.

- Continuous monitoring: Environmental sensors powered wirelessly can operate 24/7, monitoring temperature, humidity, and other factors to ensure compliance with FSMA’s Sanitary Transportation Rule.

- Cost and maintenance savings: Over-the-air charging eliminates the need for frequent battery replacements, reducing downtime and operational costs.

- Scalability: These systems are easy to expand, allowing businesses to adapt to evolving FSMA requirements without overhauling their infrastructure.

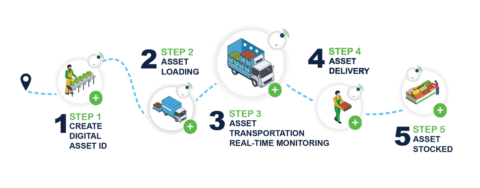

To fully comply with FSMA regulations, businesses must ensure complete traceability of food products from harvest to consumption. The diagram illustrates this process, showcasing how IoT-enabled sensors and Wireless Power Networks (WPNs) enhance visibility at every stage. First, harvested items are tagged with IoT sensors, creating a digital asset ID that allows real-time tracking of location, temperature, and handling conditions. Next, the food is actively cooled, packaged, and assigned a Traceability Lot Code (TLC) to maintain consistency throughout the supply chain. As the packaged goods are transported, sensors continuously monitor environmental conditions to ensure proper storage and prevent spoilage. Once the shipment arrives at its final destination—whether a grocery store, warehouse, or restaurant—tracking continues, providing real-time data on location and handling. Finally, when the products are stocked and ready for sale, businesses have full traceability, ensuring compliance with FSMA standards while maintaining quality and safety.

By deploying WPNs, companies can better comply with regulatory changes while building resilient and future-proof supply chains.

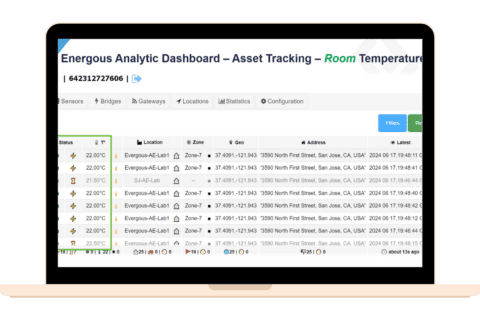

Energous Transmitters: The Backbone of Wireless Power Networks

At the core of WPNs are solutions like Energous’ PowerBridge transmitter systems, which provide over-the-air power to IoT devices. Unlike traditional wired or battery-powered setups, the transmitters deliver energy completely wirelessly, providing power within approximately 15 feet for low-power IoT devices and up to 100 feet for tags. No more cumbersome wires or frequent battery replacements—simply set up the transmitter, and devices charge automatically. Additionally, these transmitters enable two-way functionality, not only delivering power but also facilitating data transmission through a gateway for seamless monitoring and communication.

While traditional supply chain solutions provide visibility in the mid-80% range, Energous-powered WPNs deliver 95%+ real-time visibility, giving businesses deeper, more reliable insight into food movement, storage conditions, and regulatory compliance. This increased transparency enables:

• Real-time, end-to-end traceability: Businesses gain deeper insight into food movement, storage conditions, and regulatory compliance at every stage.

• Proactive issue detection: Instant alerts when temperature, humidity, or location parameters deviate from FSMA requirements, reducing the risk of non-compliance.

• Elimination of power-related downtime: Devices no longer fail due to battery depletion, ensuring uninterrupted tracking and environmental monitoring.

Preparing for the Future of Food Safety

As the FSMA continues to evolve, compliance will require increasingly sophisticated technologies to keep up with new standards. The upcoming FSMA Rule 204 mandates that by January 20, 2026, companies involved in the supply chain must maintain detailed records of food products to enhance traceability.

To meet this deadline, businesses must proactively invest in scalable, efficient, and connected systems now. Early adoption not only ensures compliance but also provides a competitive edge by optimizing operations and futureproofing for upcoming regulations.