The global supply chain is under pressure. Companies are being pushed by consumers and legislation to increase visibility and monitor every stage of logistics, warehousing, and transit. The only viable way to accomplish this is with mass deployments of sensors and ambient IoT devices across supply chains. But here’s the catch: most of those sensors rely on batteries or hardwiring and that just doesn’t scale.

Battery-powered sensors fail. Often. In the field, batteries advertised for 12 months frequently need replacement in 6 months (Fafoutis et al., 2018), causing data outages, a loss of visibility, and human intervention to replace that battery – something that gets expensive fast. Cabled power brings its own problems, requiring intensive labor via installation & maintenance, high cost of deployment, and making it nearly impossible to deploy in complex or moving environments like delivery fleets, cargo containers, cold storage, and dynamic warehouse zones.

These are the key pain points Wireless Power Networks (WPNs) solve and why they scale so effectively where traditional methods fail.

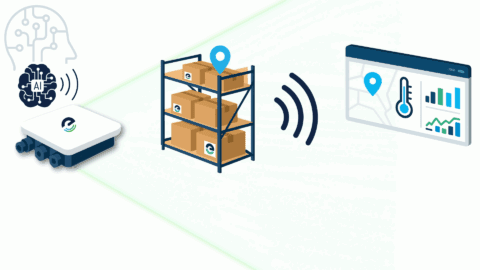

WPNs deliver power over-the-air at a distance. No batteries or cables – just continuous, reliable energy that allows devices to run and continuously transmit data maintenance-free. WPNs also serve as a data gateway, enabling both power and data to move through the same system, meaning fewer outages and way more data.

To break it down:

• No batteries = no replacements, no downtime.

• No wires = easier, faster deployments, even in places where traditional deployments aren’t possible.

• Data + power through a single network = less complexity, more reliability.

As a result, companies can now scale up their visibility without scaling up their maintenance budget. They can monitor assets in real-time, even in places that were previously incredibly difficult like refrigerated trucks, shipping containers, or vast open-air logistics yards. Supply chain leaders are demanding continuous visibility. Wireless power networks make that possible.